Have you ever stopped to think about where your electricity comes from? Beyond the wall socket and the power lines, lies a complex and often unseen world of energy generation. One of the most fascinating and reliable sources is hydropower, harnessed from the force of flowing water using dams. But how do these colossal structures actually work? What are the essential pieces that allow them to convert the power of a river into the electricity that lights our homes?

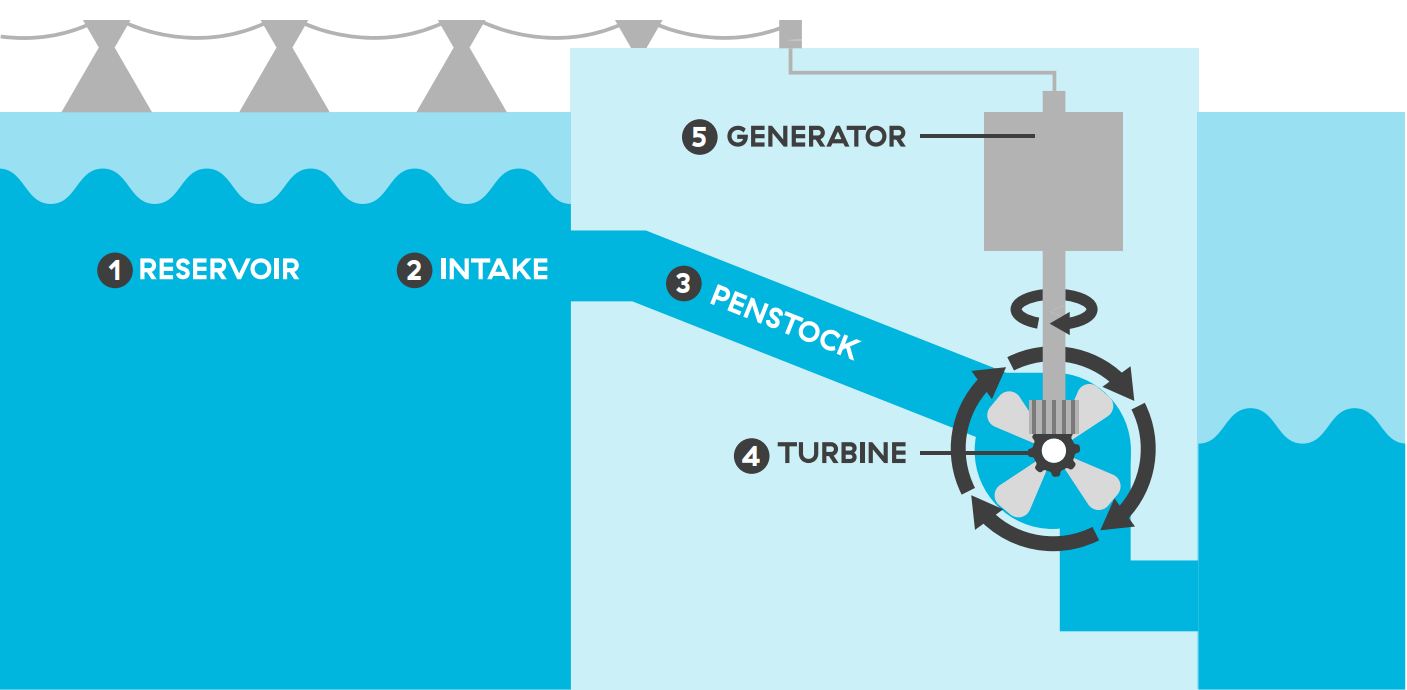

Understanding the intricacies of hydroelectric dams can feel like diving into a technical abyss. Jargon like "penstocks" and "turbines" can be intimidating, and visualizing the entire process from reservoir to power grid can be a challenge. It's easy to feel lost in the details and miss the bigger picture of how these impressive engineering feats contribute to our energy landscape.

This blog post aims to demystify the world of hydro energy dam systems by breaking down the key components and explaining how they work together. We'll explore the essential elements of a dam, from the massive structure itself to the turbines that spin to generate electricity. By the end, you'll have a clear understanding of how these systems operate and their significance in the world of renewable energy.

We'll journey through the anatomy of a hydro energy dam system, starting with the dam structure, then diving into the spillways, intake, penstock, power house, turbines, generators, transformers, and finally, the outlet works. We'll unravel how each component plays its vital role in converting the potential energy of water into the electricity that powers our daily lives. Think of it as a guided tour through one of the most impressive feats of engineering, all geared towards understanding a vital source of renewable energy.

The Dam Structure: Foundation of Power

The dam structure is arguably the most visible and impressive component of a hydroelectric system. Its primary purpose is to create a reservoir by blocking a river or stream. This reservoir stores a large volume of water at a higher elevation, creating potential energy. I remember visiting the Hoover Dam as a kid and being absolutely awestruck by its sheer size. It wasn't just a wall of concrete; it was a testament to human ingenuity, holding back the mighty Colorado River. That experience sparked my curiosity about how dams work and the critical role they play in generating power.

There are several types of dam structures, each suited to different geological conditions and river characteristics. Gravity dams, like the Hoover Dam, rely on their immense weight to resist the force of the water. Arch dams, on the other hand, are curved structures that transfer the force of the water to the canyon walls. Embankment dams are constructed from compacted earth or rockfill and are typically used in wider valleys. The selection of dam type depends on factors like the river's flow rate, the surrounding geology, and the desired reservoir capacity. Without the dam, there would be no stored water and consequently, no potential energy to convert into electricity. It's the foundational element upon which the entire hydroelectric system is built. The height of the dam dictates how much potential energy can be stored; the higher the dam, the larger the reservoir and the greater the "head" (the vertical distance the water falls), leading to increased power generation capabilities. The dam also regulates the flow of water, allowing for controlled release to meet electricity demand.

The Spillway: A Safety Valve

The spillway is a crucial safety feature of any dam system. Its primary function is to release excess water from the reservoir, preventing the dam from being overtopped during periods of heavy rainfall or snowmelt. Think of it as a relief valve, ensuring the structural integrity of the dam and preventing catastrophic flooding downstream. The design of a spillway varies depending on the dam type and the expected flood conditions. Some spillways are simple concrete channels that divert water around the dam, while others are more complex structures with gates that can be opened or closed to control the flow. Without an adequate spillway, a dam could be at risk of failure during extreme weather events. Overtopping can erode the dam's foundation and potentially lead to a breach, causing devastating downstream flooding. Spillways are designed to handle the probable maximum flood (PMF), which is the largest flood that could reasonably be expected to occur at a particular location. This is determined using historical data, hydrological models, and statistical analysis. In addition to protecting the dam, spillways also help to maintain a stable reservoir level, which is essential for efficient power generation. By controlling the flow of water through the spillway, operators can ensure that the turbines receive a consistent supply of water.

The Intake: Channeling the Flow

The intake is the point where water is drawn from the reservoir into the penstock. It's designed to efficiently capture water while preventing debris, such as logs and sediment, from entering the system. The intake structure typically includes screens or trash racks to filter out larger objects that could damage the turbines. Its location is carefully chosen to optimize water flow and minimize turbulence. A well-designed intake can significantly improve the efficiency of a hydroelectric system. Turbulence and debris can reduce the flow rate and damage the turbine blades, leading to decreased power output and increased maintenance costs. Intakes are often located at a specific depth in the reservoir to draw water from the zone with the best water quality and temperature. This can help to prevent problems with corrosion and biofouling in the penstock and turbines. Some intakes are equipped with adjustable gates or valves that allow operators to control the amount of water entering the penstock. This is important for regulating power generation and responding to changes in electricity demand. The intake is more than just a hole in the dam; it's a carefully engineered structure that plays a vital role in ensuring a reliable and efficient flow of water to the turbines. Choosing the right location and designing an effective intake is crucial for the overall performance of the hydroelectric system.

The Penstock: A Water Highway

The penstock is a large pipe or tunnel that carries water from the intake to the turbines. It's designed to withstand the high pressure of the water and to minimize energy loss due to friction. Penstocks can be made of steel, concrete, or other durable materials, depending on the size of the dam and the water pressure. The diameter of the penstock is carefully calculated to ensure that the turbines receive the optimal flow rate. The length of the penstock can vary from a few meters to several kilometers, depending on the distance between the dam and the power house. The penstock is a critical component of the hydroelectric system because it directly affects the amount of power that can be generated. A well-designed penstock will minimize energy loss and ensure that the turbines receive a steady and reliable flow of water. Penstocks are often buried underground or encased in concrete to protect them from damage and to maintain a stable temperature. This also helps to reduce noise and vibration. The design of the penstock must take into account the geological conditions of the surrounding area. In areas with unstable soil, the penstock may need to be supported by special foundations or reinforced with additional materials. Regular inspections and maintenance are essential to ensure the integrity of the penstock. Cracks or leaks can lead to significant energy loss and potentially cause structural damage to the dam.

The Powerhouse: Where Energy Transforms

The powerhouse is the heart of the hydroelectric dam system. It houses the turbines, generators, and other equipment that convert the potential energy of water into electricity. The powerhouse is typically located at the base of the dam, close to the turbines. Its size and design depend on the number and size of the turbines and generators. The powerhouse is a complex and highly automated facility, with sophisticated control systems that monitor and regulate the operation of the hydroelectric system. It's a carefully orchestrated dance of engineering and technology. The powerhouse must be designed to withstand the forces generated by the turbines and generators. It must also be protected from flooding and other environmental hazards. The powerhouse typically includes a control room where operators can monitor and control the operation of the hydroelectric system. This allows them to respond to changes in electricity demand and to troubleshoot any problems that may arise. The powerhouse is a critical component of the hydroelectric system because it's where the energy transformation takes place. Without a well-designed and properly maintained powerhouse, the hydroelectric system cannot generate electricity efficiently. Inside the powerhouse, you'll often find a bustling hum of machinery and a palpable sense of power. It's a testament to human ingenuity and our ability to harness the forces of nature for the benefit of society.

The Turbine: Spinning Power

The turbine is the component that converts the kinetic energy of the flowing water into mechanical energy. It's essentially a large wheel with blades that are designed to capture the force of the water. There are several types of turbines, each suited to different water flow rates and head heights. The most common types are Francis turbines, Kaplan turbines, and Pelton turbines. Francis turbines are used for medium head and medium flow applications. Kaplan turbines are used for low head and high flow applications. Pelton turbines are used for high head and low flow applications. The turbine is a precision-engineered machine that must be carefully balanced and maintained to ensure efficient operation. The blades of the turbine are designed to maximize the amount of energy that is extracted from the water. The turbine is connected to a generator, which converts the mechanical energy into electrical energy. The speed of the turbine is carefully controlled to maintain a constant frequency of electricity. The turbine is a critical component of the hydroelectric system because it's the point where the energy transformation begins. Without an efficient turbine, the hydroelectric system cannot generate electricity effectively. Modern turbines are often equipped with advanced sensors and control systems that optimize their performance. This allows them to respond to changes in water flow and electricity demand. Regular maintenance and inspections are essential to ensure the long-term reliability of the turbine. Damaged or worn blades can reduce the efficiency of the turbine and potentially lead to more serious problems.

Generators: Converting Mechanical to Electrical

The generator is directly coupled to the turbine and converts the mechanical energy from the spinning turbine into electrical energy. Inside, coils of wire rotate within a magnetic field, inducing an electric current. The output is alternating current (AC) electricity. The size and capacity of the generator are matched to the turbine's power output. Regular maintenance is critical to ensure efficient and reliable power generation. Generators rely on the principles of electromagnetic induction, discovered by Michael Faraday. When a conductor, like a wire, moves through a magnetic field, it generates an electromotive force (EMF), which drives the flow of electrons, creating electricity. The generator's rotor, connected to the turbine, spins rapidly, causing the coils of wire to pass through the magnetic field created by powerful magnets (either permanent or electromagnets). The faster the rotor spins and the stronger the magnetic field, the more electricity is generated. Generators are built to withstand immense forces and extreme operating conditions. They are typically housed in robust casings and equipped with cooling systems to prevent overheating. The electrical output of the generator is carefully monitored and controlled to ensure a stable and consistent supply of electricity to the power grid. Generators are not only used in hydroelectric power plants but also in other forms of energy generation, such as coal-fired power plants, nuclear power plants, and wind turbines. The fundamental principle of electromagnetic induction remains the same, regardless of the energy source.

Transformers: Stepping Up the Voltage

Transformers play a vital role in preparing the electricity generated for transmission over long distances. They "step up" the voltage of the electricity produced by the generators to a much higher voltage. This reduces current, minimizing energy loss during transmission through power lines. I was once told that transmitting electricity at low voltage over long distances is like trying to push water through a narrow pipe – you lose a lot of it along the way. By increasing the voltage, we can use a "wider pipe" and transport more electricity with less loss. The transformer is a simple but ingenious device that relies on the principle of electromagnetic induction. It consists of two or more coils of wire wound around a common iron core. When alternating current flows through one coil (the primary coil), it creates a magnetic field that induces a voltage in the other coil (the secondary coil). The ratio of the number of turns in the primary and secondary coils determines the voltage transformation. For example, if the secondary coil has ten times more turns than the primary coil, the voltage will be stepped up by a factor of ten. Transformers are essential for efficient and reliable power transmission. By reducing energy loss, they allow us to transport electricity over long distances without significant power degradation. They also play a critical role in distributing electricity to homes and businesses, stepping down the voltage to safer levels for everyday use.

Outlet Works: Returning the Water

The outlet works are the structures that release the water back into the river downstream of the dam. These structures ensure that the water is discharged in a controlled manner, minimizing erosion and protecting the aquatic environment. The design of the outlet works depends on the size of the dam and the characteristics of the river. Some outlet works are simple channels that discharge water directly into the river, while others are more complex structures with gates and valves that control the flow. The amount of water released through the outlet works is carefully regulated to maintain a healthy river ecosystem. Too little water can harm aquatic life, while too much water can cause flooding. The outlet works are also designed to prevent sediment from building up in the reservoir. Sediment can reduce the storage capacity of the reservoir and interfere with the operation of the hydroelectric system. The outlet works typically include a sediment flushing system that removes sediment from the reservoir and discharges it downstream. The outlet works are an essential part of the hydroelectric system because they ensure that the water is returned to the river in a safe and environmentally responsible manner. They are a critical link in the water cycle and play a vital role in maintaining the health of our rivers and ecosystems. Regular monitoring and maintenance are essential to ensure the proper functioning of the outlet works. Clogged or damaged outlet works can lead to flooding and other environmental problems.

Fun Facts About Hydro Energy Dam Systems

Did you know that the Three Gorges Dam in China is the largest hydroelectric dam in the world? Its reservoir stretches for over 600 kilometers! Or that the first hydroelectric power plant in the United States was built in Appleton, Wisconsin, in 1882? Hydroelectric dams have a rich history and continue to play a vital role in global energy production. The technology behind hydroelectric dams has evolved significantly over the years. Early dams were relatively simple structures, but modern dams are complex feats of engineering, incorporating advanced materials, sophisticated control systems, and cutting-edge turbine designs. Hydroelectric power is a renewable energy source because it relies on the natural water cycle. As long as there is rainfall and rivers, hydroelectric dams can continue to generate electricity. However, it's important to note that dams can also have environmental impacts, such as altering river ecosystems and affecting fish migration. Responsible dam management is crucial to minimize these impacts and ensure the long-term sustainability of hydroelectric power. Hydroelectric power is often used to provide baseload power, which is the minimum amount of electricity that is required to meet demand at all times. It can also be used to provide peaking power, which is the additional electricity that is needed to meet demand during periods of high use. The flexibility of hydroelectric power makes it a valuable asset in the energy mix. Some hydroelectric dams are also used for flood control, irrigation, and recreation. These multi-purpose dams provide a variety of benefits to society. As we look to the future, hydroelectric power is likely to continue to play an important role in the global energy transition. With responsible planning and management, it can be a sustainable and reliable source of clean energy.

How Hydro Energy Dam Systems Work

The process begins with a dam built across a river, creating a reservoir of stored water. This water possesses potential energy due to its elevation. When water is released from the reservoir, it flows through the intake and into the penstock, a large pipe that channels the water towards the powerhouse. Inside the powerhouse, the water strikes the blades of a turbine, causing it to spin. The turbine is connected to a generator, which converts the mechanical energy of the spinning turbine into electrical energy. The electricity is then transmitted through power lines to homes and businesses. Dams have evolved to be safer and more efficient, incorporating spillways for flood control and fish ladders to minimize impact on local ecosystems. Hydroelectric power can generate clean, reliable, and renewable electricity, but it is also a complex and multi-faceted technology. Understanding the key components of a hydro energy dam system is crucial for understanding how it works, its benefits, and its challenges. By harnessing the power of water, we can generate clean and sustainable energy for generations to come. With careful planning and management, hydro energy can be a vital part of our future energy mix. Hydroelectric power generation is a balancing act. Dam operators must carefully manage the flow of water to meet electricity demand while also ensuring that the river ecosystem remains healthy. This requires a deep understanding of hydrology, ecology, and engineering.

What if Hydro Energy Dam Systems Didn't Exist?

Imagine a world without hydroelectric dams. The impact on our energy supply would be significant. We would likely rely more heavily on fossil fuels, leading to increased greenhouse gas emissions and air pollution. In many regions, hydroelectric power provides a significant portion of the electricity supply. Without it, those regions would need to find alternative sources of energy to meet demand. The cost of electricity could also increase, as fossil fuels are often more expensive than hydroelectric power. Hydroelectric dams also provide other benefits, such as flood control, irrigation, and recreation. Without dams, these benefits would be lost. Flooding would become more frequent and severe, and farmers would have less water for irrigation. Reservoirs created by dams provide opportunities for boating, fishing, and other recreational activities. Without these reservoirs, those opportunities would be limited. The loss of hydroelectric power would have a ripple effect throughout the economy. Industries that rely on cheap and reliable electricity, such as manufacturing and agriculture, would be particularly affected. Our reliance on hydroelectric power reminds us how integrated our energy systems have become. It's a good idea to be more careful of our energy consumption.

Listicle of Hydro Energy Dam Systems

Here's a quick rundown of the key components of a hydro energy dam system:

- Dam Structure: Creates a reservoir and stores potential energy.

- Spillway: Releases excess water to prevent overtopping.

- Intake: Channels water from the reservoir to the penstock.

- Penstock: Carries water to the turbines.

- Powerhouse: Houses the turbines and generators.

- Turbine: Converts kinetic energy into mechanical energy.

- Generator: Converts mechanical energy into electrical energy.

- Transformer: Steps up the voltage for transmission.

- Outlet Works: Releases water back into the river.

These components work together to convert the potential energy of water into the electricity that powers our lives. Understanding these key elements allows you to appreciate the impressive engineering and technology behind hydroelectric power. Each component is carefully designed and maintained to ensure efficient and reliable operation. Hydroelectric dams are a testament to human ingenuity and our ability to harness the forces of nature for the benefit of society. They provide clean, renewable energy, flood control, irrigation, and recreation. With responsible management, they can continue to play a vital role in our energy future. The integration of these components into a single, functional system requires careful planning, design, and construction. It is an art form of balancing ecological impact with energy requirements.

Question and Answer About Hydro Energy Dam Systems

Q: What are the main advantages of hydroelectric power?

A: Hydroelectric power is a renewable energy source, meaning it relies on a naturally replenishing resource (water). It also produces no greenhouse gas emissions during operation and can provide flood control and irrigation benefits.

Q: What are some of the environmental concerns associated with hydroelectric dams?

A: Dams can alter river ecosystems, block fish migration, and inundate land. Careful planning and mitigation measures are essential to minimize these impacts.

Q: How does a turbine work in a hydroelectric dam?

A: A turbine is essentially a large wheel with blades. When water flows through the turbine, it strikes the blades, causing the wheel to spin. This spinning motion is then used to generate electricity.

Q: What is the role of a transformer in a hydroelectric dam system?

A: A transformer steps up the voltage of the electricity produced by the generators to a higher voltage, which is more efficient for transmitting electricity over long distances.

Conclusion of Hydro Energy Dam Systems: Key Components Explained

Hydro energy dam systems are complex but vital components of our energy infrastructure. By understanding the function of each key part – from the dam structure to the outlet works – we gain a deeper appreciation for the engineering marvels that provide us with clean and reliable electricity. While environmental considerations are paramount, the continued development and responsible management of hydroelectric power can play a significant role in a sustainable energy future. Remember, the next time you flip a light switch, the power might just be coming from the impressive force of water harnessed by a hydro energy dam.